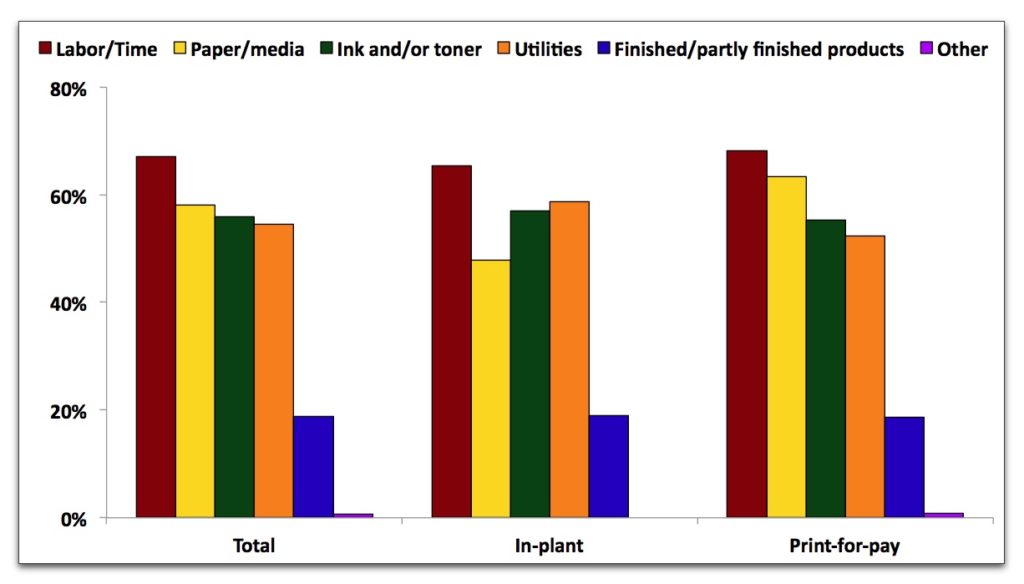

In the 2014 InfoTrends report Production Print Services in North America: Understanding Industry Transformation, respondents were asked, “Which waste elements do you track?” The data was segmented by “print for pay” companies, also known as commercial printers, as well as in-plant printers.

As you can see in the table below, the vast majority of responses were similar when we compared the commercial printers to the in-plant printers. The largest difference was in the tracking of waste paper and other media. Of the commercial printers, 63% said they tracked paper and media waste compared to 47% of the in-plant printers.

Why is tracking waste this important?

Without going into agonizing details about the differences between waste and spoilage and the different percentage of waste associated with different printing and finishing processes, let’s just say that waste includes any paper or media that is thrown away. The important question is how paper waste increases charges or hinders an in-plants ability to break even?

In the simplest of terms, paper is one of the most expensive components of the printing process. The percentage of cost due to paper waste varies based on the run length, the printing process, and the kind of paper used, but a typical rule of thumb for on-demand digital printing is about 10%.

This becomes a problem when paper waste is doubled by people we refer to as the worst offenders.

Who are the worst offenders and what is their impact?

There are three ways to define the worst offenders. They can be: staff that don’t understand how to prepare files for output, customers who don’t prepare files well, and staff that don’t understand how to preflight and repair customer files. In all three cases, the worst offenders create more mistakes and paper waste.

The impact of the worst offenders is that paper waste is two or more times higher than the industry-standard. A study conducted by Lexmark (2006) found that an average of 17% of everything printed was considered waste or pages the user didn’t want.

One project we worked with was a $2 million company with six high speed digital presses. They were struggling with on-time delivery, suffered from customer complaints of price, and they were losing money. It did not take long to uncover that they threw too much paper away. We estimated they created 25% waste, which made them one of the worst offenders.

Benefits of overcoming waste issues

The good news is that we helped them create a monitoring process and worked with staff on quality procedures to reduce waste. In the end, waste was reduced by 50% and they:

- Did not need additional equipment

- Could reduce their prices while increasing customer satisfaction

- Achieved break-even

Something to think about:

- Are you part of the 53% of in-plants unaware of your paper waste?

- When was the last time you measured paper waste?

- Was it done recently or was it when you have different equipment?

- Is your percentage within industry standards?

- How do you reduce your waste?

—

Howie Fenton is Associate Director of Operational Consulting at InfoTrends. For 25 years, he has worked with in-plants and commercial printers on: benchmarking operational and financial performance, recommendations to increase productivity/reduce costs and strategies to increase value.To email click here.