If our experience is any indication of a trend, we believe there is a renaissance of interest in operational measurements, benchmarking performance and identifying and fixing gaps in performance. Years ago, this was very important in the printing industry. I remember twenty years ago as a member of the GATF consulting team, there were seven people focusing on measurements and benchmarking programs in the industry.

What is the motivating factor behind this renewed interest? We believe that part of it is due to the fast and ever changing rush to adopt digital production tasks. For years this rush was frantic as companies had to try to keep up with the fast pace of change. For two decades there was at least one, if not two, major technology changes impacting print production. These changes included desktop typesetting, desktop scanning, desktop color correction, Print MIS software, imagesetter/CTP devices, pdf workflow software, color management software, variable data software, and web to print offerings.

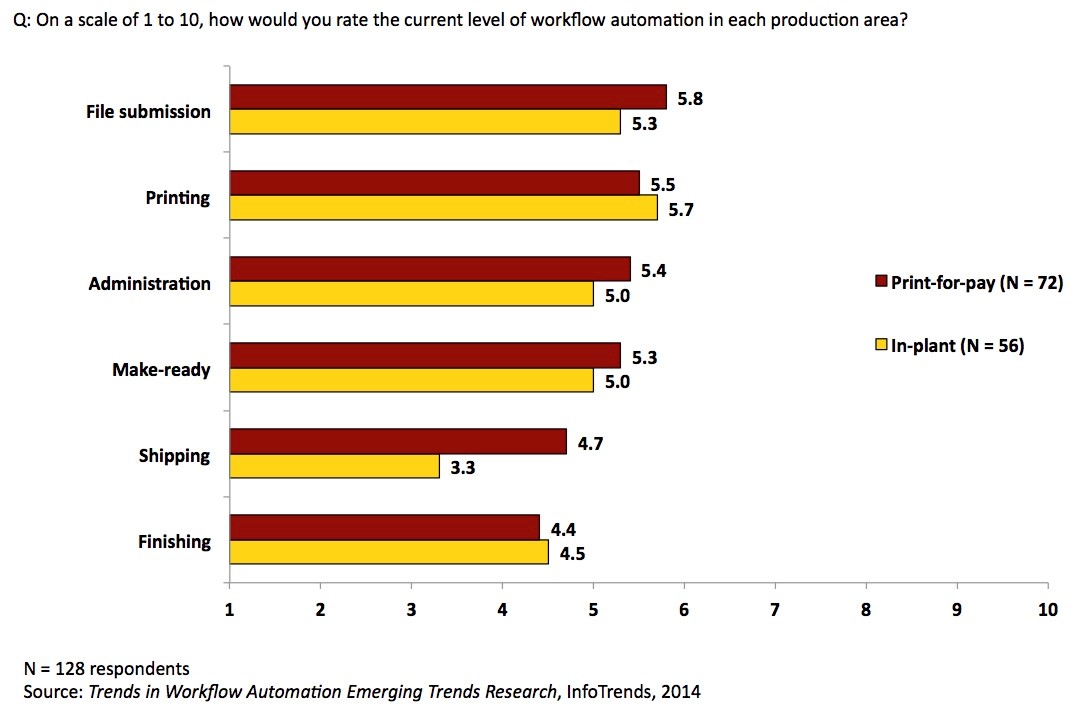

This rush to constantly adopt new digital technologies and learn on the fly resulted in many companies playing catch up and never mastering some technologies, which explains why many companies report only 50% productivity.

As you can see in this chart from the InfoTrends Study, Trends in Workflow Automation, when companies were asked to rate the level of automation in their manufacturing operations, the average was approximately 5 out of 10.

How to Increase Productivity

In a White Paper, “How Much Time, Money, and Opportunity are You Wasting?” we talk about the traditional waxing and waning of interest in reducing waste and increasing productivity. In the past twenty years, we have seen that the interest declines during times of high demand and growth. During slow periods and economic hardships, the interest increases. For example, during the most recent recession and slow painful recovery which followed, there was an ongoing emphasis on increasing productivity to retain competitive prices in an attempt to retain profit margins.

Although painfully slow, as the economic conditions continue to improve, we would expect a reduction of interest in increasing productivity. Interestingly, however, that is not the case. We are seeing continuing interest. In the last four months we have worked on three assignments that focused on measuring, benchmarking, and working to increase productivity.

As a result, we believe that the pendulum is no longer swinging back and forth. But why? It may be because in-plant printers and print buyers working with commerical printers are focusing on sustainability policies and programs designed to reduce paper usage.

This impacts the value of the in-plant who have to align with strategy or the parent organization, and commerical printers who have to demonstrate sustainability efforts to remain on the list of approved vendors.

If you’re interested in learning more about reducing waste and increasing productivity, please feel free to download the InfoTrends White Paper, “How Much Time, Money, and Opportunity are You Wasting?”

—

Howie Fenton is Associate Director of Operational Consulting at InfoTrends. For 25 years, he has worked with in-plants and commercial printers on: benchmarking operational and financial performance, recommendations to increase productivity/reduce costs and strategies to increase value.To email click here.